Services

Our Services we offer

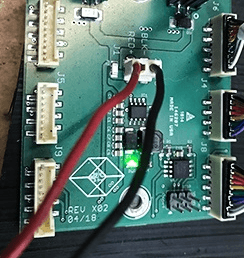

Prototypes

Concept, Design, and Build Product Prototypes

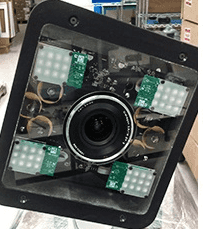

Lab Equipment

Design and Build Custom Lab Equipment

Manufacturing

In-house Machining and Fabrication

Testing

Testing of your products or equipment

Like what you see? Email me at [email protected] for a quote!